Precision and efficiency are paramount in modern metal fabrication. In fact, it is going to impact metal making even in a workshop, fabrication shop, or DIY project at home. It's one of the tools that has revolutionized its field because it utilizes the process of plasma cutting. It becomes a game-changer for precise and consistent high-quality metalwork for an efficient plasma cutter with a table cutter. Let's explore how these table plasma cutters operate, some benefits accruing compared to the traditional methods, and the fact that, for a serious person, these tools are indispensable.

What Is a Plasma Cutter?

A plasma cutter is a highly efficient gas jet that is powered by creating a high temperature in a specific area, allowing it to pass through metals fairly quickly and provide a "clean cut" with very little distortion at the edge. Plasma cutting has several advantages over oxy-fuel cutting or some mechanical saws, including:

• Speed: Automated methods nearly always cut much faster than manual methods.

• Precision: They're burr free and leave the edges clean.

• Versatility: Works great on a wide range of metals and thicknesses.

• Low Heat Distortion: Focused heat implies that very little warping occurs within the material.

Introducing the Plasma Table Cutter

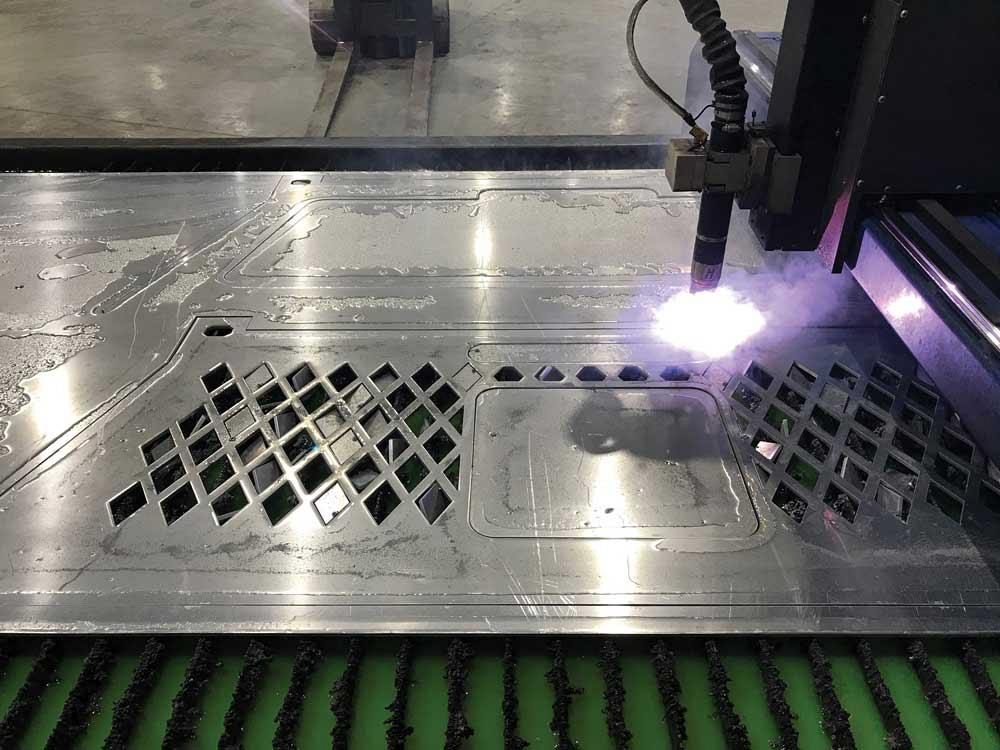

A plasma table cutter combines the benefits of using a handheld plasma cutter with the precision of a CNC-controlled table. This provides the ability to make fully automated, reproducible, and highly accurate cuts in sheets of all sizes.

Core elements of a table cutter include:

• CNC Table: Moves the metal or cutting head with computer-controlled precision.

• Plasma Torch: The cutting tool that produces the plasma arc.

• Software Interface: Manages the complex setup and execution of patterns.

• Support Grid/Table Surface: Holds the metal plate firmly during the cutting operation.

These devices convert plasma cutting into a much more automated and highly efficient activity as opposed to the classic manual, labor-intensive process.

Benefits of Plasma Cutter

1. Unmatched Precision

CNC control ensures highly accurate and consistent cuts. These complex designs, curves, and intricate patterns could never have been created any other way without hours being spent with a handheld plasma cutter.

2. Increased Productivity

Automation requires less manual operation, thus allowing workers to devote more time to other projects. In one setup, multiple pieces can be cut out, thereby shortening the production time and labor costs.

3. Best Material Utilization

The best places to put different parts on a sheet of metal, with a minimum of waste and cost savings on materials, can be achieved by CNC programming.

4. Versatility

They can accommodate various metals with many different thicknesses, whether for custom production, industrial, or artistic applications.

5. Safety

Keeping the operator away from sparks, heat, and fumes directly reduces the risk of injury compared to manual cutting.

Who Can Benefit From a Plasma Cutter?

The plasma cutter is widely applicable to end users, including:

• Fabrication Shops: Reduces direct costs for improved cut quality.

• Industry Manufacturers: Handles large production volumes effectively.

• Hobbyists and Makers: Allows precision cutting for custom works.

• Artisans: Precision and decorative designs in metal.

With modern speed and control, a plasma table cutter comes along with flexibility in terms of plasma cutting.

Choosing the Right Plasma Cutter

The factors to keep in mind when choosing a plasma cutter include the following:

• Cutting Capacity: Maximum metal thickness and sheet size.

• Automation Features: CNC capabilities and software compatibility.

• Durability: Built with high-quality materials for long-lasting performance.

• Support and Maintenance: Technical support availability regarding the use of the product and spare parts.

• Cost vs. Return: Determine the effects of improved efficiency on the business's profitability, lowered overheads due to less wasted time and materials, as well as better quality. Investing in a good plasma cutter goes a long way towards improving one's workflow, product quality, and customer satisfaction.

Final Thoughts

Conversion of a plasma cutter into a plasma table cutter provides precision and speed in metalwork. Efficiency and versatility are advantages that anyone undertaking precision metalwork will enjoy from this system. Waste reduction, handling complex designs, is a game-changer for workshops, fabrication shops, and metal artists. Use either of the two styles if you want to upgrade your tools or launch a new fabrication business; a plasma cutter invests in quality, speed, and productivity.

Comments